The Importance Of Installation & Commissioning Checks

Installation and Commissioning checks are one of the most important tasks when you purchase a new Gas Detection System; they are required for the safety of staff and to ensure the correct function of your equipment.

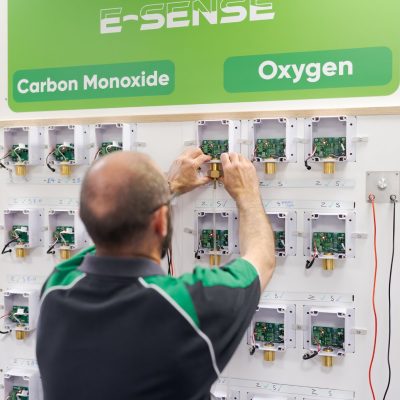

Installation checks ensure the correct wiring and mounting of Gas Detection equipment. These include termination checks and voltage checks. You will also want to double check all connections to prevent potential equipment damage.

Other important factors to consider and access when mounting the gas detector are room size, target gas (is it lighter, heavier or neutral in air), any obstruction to airflow of the target gas to the detector, non-condensing environment and other heavy machinery nearby.

Commissioning is the act of “function testing” a Gas Detection system as a completely installed system. This is done with a suitable certified calibration gas. This process verifies that the gas detectors are performing their function correctly and are not just powered on. The response of the detector can be seen on the Gas Detection controller and the associated responses are then shown on the audio/visual alarms, exhaust fans or shut off equipment.

The commissioning checks are performed after the system is completely installed and is as it will be in continued operation. We always recommend that the Commissioning is completed by a third party not the installer so that items do not get forgotten or steps overlooked.

Please note that Gas Detection (Australia) Pty Ltd is happy to travel Australia wide to commission your installed system.

If you would like to speak with us about our commissioning services, please get in contact with us here.

Alternatively, you can learn more on Commissioning here.