Safety has been always our Priority

When gas leaks occur, it only takes seconds to spread into a large room. It is highly difficult to detect if a portable or fixed gas detector is not used to detect the leak. This can impact negatively on employees’ health that ranges from a slight headache to even death, not to mention the harm to the environment and your business.

The effects of gas exposure of unseen danger and environments that you do not think could cause a problem can be long-lasting. Gas exposure can be as simple as sitting in a room with too many people and not enough fresh air movement or confined spaces, this will cause the Carbon Dioxide levels to rise, and your staff will leave feeling drained and maybe with a headache. You must remember that gas can come in many different variants and therefore has many different outcomes when something goes wrong. These can range from a headache to an explosion because someone left the gas turned on at a stove or gas point in a lab, or even a refrigerant leak from an air-conditioner.

In order to prevent the consequences of a gas leak in a company, the appropriate Process Hazard Analysis (PHA) must be applied. Every process for prevention is highly valuable, and companies must cover every process in extreme detail.

In May of this year, a well-known Chemical company in Queensland had a massive leak of Carbon Dioxide and Nitrous Oxide gases into the atmosphere, due to equipment failure, which cost the company more than $5 million on repairs and reassurance to the local surrounding community.

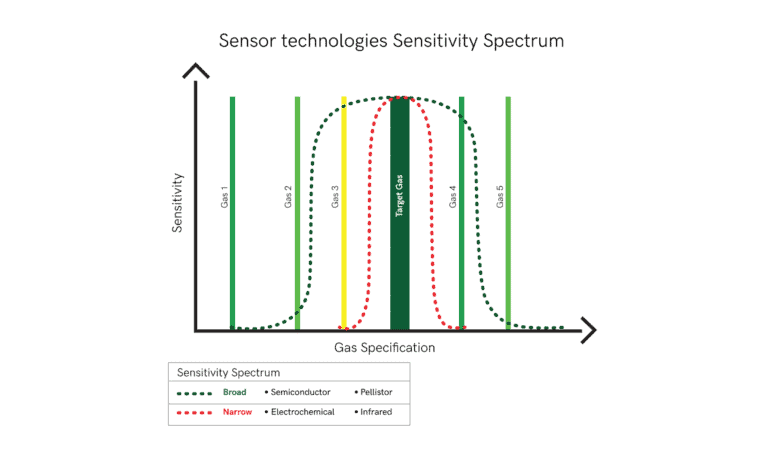

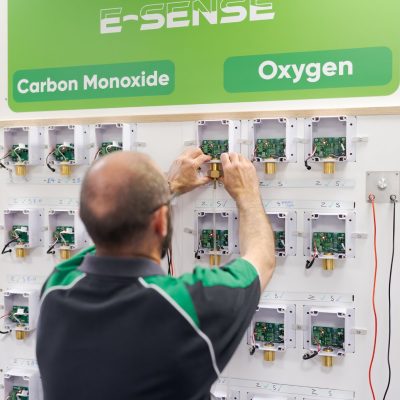

There is no risk when the correct PHA performance is applied in companies. Either a portable or fixed gas detector system is essential for the safety of your employees, helping to identify a gas leak in an early stage, preventing significant damage, including illness, serious injuries, and even death.