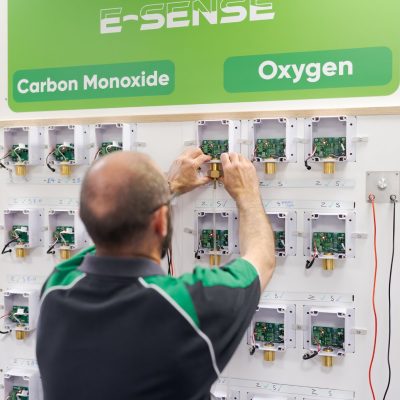

Gas Detection Devices Designed for Australia

Protecting lives and assets. Our gas detectors have been specifically made for the Australian environment and safety standards.

Australian Made

Reliable

High Quality

Experienced Support

Proudly Australian Made

Our detectors and sensors are made in Australia, for Australian safety requirements.

Gas Detection Australia has been protecting, installing, servicing, and providing gas detection products in the Australian market for more than 14 years, providing safety equipment for numerous clients all over Australia.

Our team is so experienced that we have engineered, designed, and manufactured our own line of Gas Detectors including the 2500 & 3100 series, including Controllers and other Sensors!

Keeping Your People & Assets Safe

Don’t let gas compliance go by the wayside, we’re here to be your go-to mates in all things Gas Detection compliance, ensuring your always keep your people and assets safe.

With our experienced team as your mates in Gas Detection, compliance doesn’t have to be a complex and overwhelming task. You can trust us to help you source, install and maintain the highest level of Gas Detection in your specific zones.

Your Mates in Gas Detection