-

Monday – Thursday 8:00 am – 5:00 pm

Friday 8:00 am to 4:00 pm

Products in category: Products

Showing 1–16 of 148 results

-

Non-Hazardous GTQ-BS02 Gas Detector

Our GTQ-BS02 fixed gas detector is designed for industrial and commercial use. By adopting high-performance gas sensors. This non-hazardous detector has good repeatability, high accuracy, and a long lifespan, and it can be installed everywhere without a difficult installation. This mate is also recommended for protection against LPG leaks in restaurants and commercial kitchens.

This great gas detector can be used as a fixed gas detector and standalone (with a red alarm accessory).

-

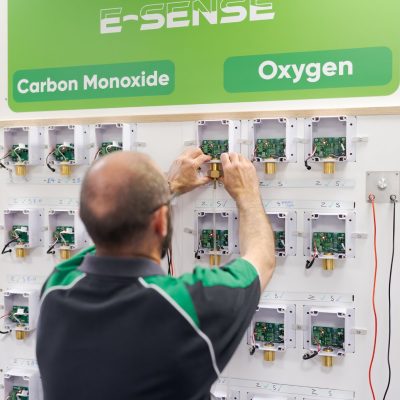

E-Sense Carbon Monoxide (CO) Electrochemical Gas Detector

E-Sense is our new signature range of electrochemical gas detector. This versatile unit boasts several great features including: 2 or 3 wire operation, ability in the the 3 wire mode to be able to connect to either 4-20mA or 0-20mA controllers, it also boasts the ability to change the sensor detection range by half, other…

-

E-Sense Ammonia (NH3) Electrochemical Gas Detector 0-1000ppm

E-Sense is our new signature range of electrochemical gas detector. This versatile unit boasts several great features including: 2 or 3 wire operation, ability in the the 3 wire mode to be able to connect to either 4-20mA or 0-20mA controllers, it also boasts the ability to change the sensor detection range by half, other…

-

iR-gas Carbon Dioxide (Infrared CO2) Gas Detector 0-5% Vol. in Brass stinting

Meet our Infrared CO2 Gas Detector iR-gas 4370 Brass stinting

Our Infrared CO2 gas detector, “iR-gas 4370”, is designed for use in safe area applications. This infrared CO2 sensor uses the latest laser semiconductor technology for the detection of carbon dioxide (CO2). This Infrared CO2 sensor and electronics are one homogenous unit and must never be separated. It has an analog output that can be set to 4-20mA, 0-20mA, 0-10V, or 0-5V. This Infrared CO2 sensor also comes in brass stinting.

-

iR-gas Refrigerant Gas Detector with Infrared Sensor

Meet our iR-gas 3100 Refrigerant Gas Detector enabled with an Infrared Sensor

Our refrigerant gas detector with infrared sensor, “iR-gas” functionality is to detect the presence of the target refrigerant gas in the air surrounding it. This refrigerant gas detector with an enabled infrared sensor is designed to be connected to a GDA gas detection controller or similar Building Management System(BMS). This infrared sensor will control the alarm systems and/or ventilation to reduce gas loss and potentially harmful situations.

Our refrigerant gas detector contains a Non-Dispersive Infra-Red (NDIR) gas sensor and is operating via natural diffusion. This sensor is designed to give long service life under normal ambient operating conditions. Its sensor technology allows greater accuracy and lower cross-sensitivity to other gases, majorly reducing false readings when other gases are present.

Our iR-gas refrigerant gas detector has the following technical features: Range: 0-1000 ppm; NDIR Sensor, Output: 4-20 mA, 0-20 mA, 0-5 VDC or 0-10 VDC, Alarm Relay, Power: 24 VDC 3-wire powered, Factory set alarm: 250 ppm, Factory Calibrated Output set to 4-20 mA.

Find the Refrigerant gases range of r134a, r410, r123, r22, and more.

-

E-Sense Ammonia (NH3) Electrochemical Gas Detector 0-300ppm

E-Sense is our new signature range of electrochemical gas detector. This versatile unit boasts several great features including: 2 or 3 wire operation, ability in the the 3 wire mode to be able to connect to either 4-20mA or 0-20mA controllers, it also boasts the ability to change the sensor detection range by half, other…

-

E-Sense Nitrogen Dioxide (NO2) Electrochemical Gas Detector Gas Sensor 0-10ppm PTFE

E-Sense is our new signature range of electrochemical gas detectors. This versatile unit boasts several great features including 2 or 3 wire operation, ability in the the 3 wire mode to be able to connect to either 4-20mA or 0-20mA controllers, it also boasts the ability to change the sensor detection range by half, other…

-

iR-gas Flush Mounted Refrigerant Gas Detector with Infrared Sensor

Meet our Flush Mounted Refrigerant Gas Detector iR-gas 3160 with Infrared Sensor

Our refrigerant leak detector with an infrared sensor functionality is to detect the presence of the target refrigerant gas in the air surrounding it. This refrigerant gas leak detector is designed to connect to a GDA gas detection controller or similar BMS system. This is to control alarm systems and/or ventilation to reduce gas loss and potentially harmful situations.

The refrigerant gas leak detector with an Infrared Sensor, contains a Non-Dispersive Infra-Red (NDIR) gas sensor, operating via natural diffusion. This sensor is designed to give long service life under normal ambient operating conditions. Also, this sensor technology allows greater accuracy and lower cross-sensitivity to other gases, majorly reducing false readings when other gases are present.

Our Flush Mounted Refrigerant Gas Leak Detector, iR-gas 3160, is suitable for indoor use only.

For external environments, contact our specialist advice from GDA.

The iR-gas mounted refrigerant gas has the following technical features: Range: 0-1000 ppm; NDIR Sensor, Output: 4-20 mA, 0-20 mA, 0-5 VDC or 0-10 VDC, Alarm Relay, Power: 24 VDC 3-wire powered, Factory set alarm: 250 ppm, Factory Calibrated Output set to 4-20 mA.

Range of Refrigerant gases: r134a, r410, r123, r22, among others.

-

-

-

-

-

E-Sense Ammonia (NH3) Electrochemical Gas Detector 0-150ppm

E-Sense is our new signature range of electrochemical gas detector. This versatile unit boasts several great features including: 2 or 3 wire operation, ability in the the 3 wire mode to be able to connect to either 4-20mA or 0-20mA controllers, it also boasts the ability to change the sensor detection range by half, other…

-

-

-

Backed by an Experienced Team of Gas Detection Professionals.

We’re here, as your mates, to advise, support and assist you at every step of your Gas Detection compliance journey.

ABN 74 124 402 231